Issue 7: Feeling

Is Wearable Technology Ready-to-Wear?

Wearing clothes has become such a ritualistic practice, that even the people least concerned with fashion, make some mental effort, when they decide to go for jeans or a jacket. We are what we wear. Every garment we wear says something about who we are, how we feel, and how we want the world to see us.

And now, wearable devices have been introduced to this daily ritual, thanks to the commercialization of personal smart wristwear. From Fitbit to Apple Watch, an increasing amount of functions have been added to the small footprint of one’s wrist. We use them to check messages, receive phone calls, track our movements, and monitor our heart rates. While these gadgets wow us with the convenience, most of their functions fall into two categories: notifications and fitness tracking.

The form factor, for example, the plastic enclosure and the USB charging port of these devices follows the standard of consumer electronics rather than that of clothing or accessories. At the core of a smartwatch, is a printed circuit board loaded with integrated circuits powered by a battery and enclosed by a plastic or silicone case. Most manufacturers of smart wristbands have taken a page from the mature, long-established consumer electronics industry. These existing standards quickly led wearable designs from prototypes to commercial products. However, if we take a look at the word wearable, it is not equivalent to a piece of an intricate electronic device with a strap. It simply describes one characteristic of one object: able to wear.

From armor to spacesuits, generations of wearables have used technologies to provide unique functions to wearers. Designer Diana Dew’s light-up mini-dresses of 1967 kick-started the era of embedding electronics into clothing. And since then, so many fashion designers have explored the possibilities of combining technology with fashion outside of the production process. IBM presented a “cognitive dress” at the 2016 Met Gala that lit up in different colors in real-time, based on tweets about the dress, using IBM’s Watson supercomputer to process the data and compute hues. The resemblance between the cognitive dress and Dew’s lit-up outfits is a telling example of how far wearable technology has progressed, but also how unresolved the future might be. Most of the innovative developments in smart clothing and wearable technology today still happen in the lab–in controlled environments, using a small number of prototype garments and devices. A wristband-styled smart device seems to be an answer to personal fitness tracking and notification, but much of our clothing and body hasn’t undergone that kind of exploration.

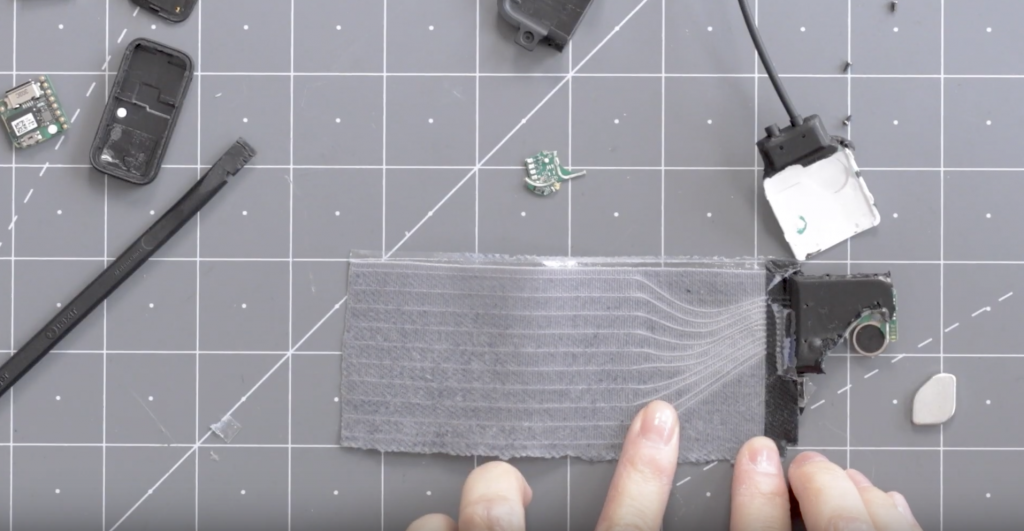

Here is an example of how wearables can be more than smart wristbands. Jacquard, a collection of conductive threads, micro-electronics and intelligent software developed by Google, allows brands to embed sensors into textiles and therefore, turns a portion of fabric into a touch-sensitive, reactive surface. Levi’s Trucker jacket is one of the products that incorporate Jacquard technology. In my recent teardown of the second iteration of the jacket with my coworkers at Tomorrow Lab, we saw a capacitive touch sensor layer sewn into the left cuff of the jacket, woven with both conductive and non-conductive fibers, and then sandwiched between two denim pieces. Paired with a mobile device, the sensor allows users to trigger a variety of apps without reaching for the phone, by utilizing different tapping and swiping gestures. It’s impressive to see that a piece of the woven sensor can distinguish different touching gestures so precisely and smoothly.

However, it is too optimistic, perhaps, if we are hoping this technique will bring intelligence, art, and entertainment to the textiles worn every day. While the circuit is well-constructed, the silicon-like insulation layer underneath the sensor stiffens the textile. This is a typical example of the current textile-based wearable technology dilemma. There are very limited types of soft components that can be sewn into fabrics, and no standard methods for soft circuit design and fabrication. In this case, except for the woven capacitive touch sensor, all the other components – including the circuit board, connectors and vibration motor – are rigid. Without having components that can be bent, twisted, or crumpled to adapt to our body movements, users will feel the slight bulkiness of the circuit.

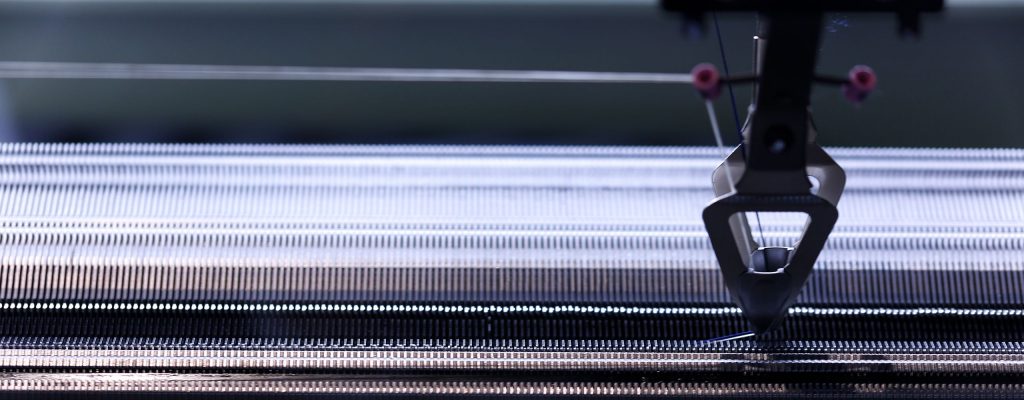

Blending conductive fibers into yarns and threads is just the first step. Even though companies such as, Google, have managed to produce electronic components in soft materials, there isn’t a foreseeable solution to mass production. Even though the Levi’s jackets can be found in stories in several countries, they were produced in much smaller quantities than the brand’s traditional denim jackets. It isn’t currently possible to mass produce fabrics that can both meet the precision needed to print circuits and look, feel, and perform like normal yarn that can be woven into interactive textiles.

Luckily, these technical hurdles are not detering fashion designers and wearable technologists from exploring the possibilities of wearables. Currently, most projects are individually designed and crafted for specific performances or showcases. London-based fashion and technology company Studio XO, for example, has designed a series of items, including a flying costume and a bubble-blowing dress for Lady Gaga. (NO)WHERE (NOW)HERE, a project by Montreal-based fashion designer Ying Gao, comprises two dresses made from photoluminescent thread that slowly change their shape based on the spectator’s glances. Compared to smartwatch manufacturers, these designers treat wearable technology as digital couture, rather than consumer electronics. And even though they are largely one-off samples, they provide an alternative to smart wristbands, allowing for new experiments.

To predict the future of wearables, it’s important to consider the history of the clothing industry, which shifted gradually from bespoke to ready-to-wear in the 19th century thanks to changing demand and emerging technology. Before the extensive production of ready-to-wear clothing, each garment was made individually. The sizes were measured to the wearer and cut-and-sewn by tailors. The earliest version of men’s ready-to-wear sizes occurred during the American Civil War. The immediate need for uniforms proliferated the demand for high-quality and mass-produced uniforms and the invention of foot-treadle sewing machines allowed workers to piece garments together quickly. To speed up the production, measurements were taken of men and grouped into the now familiar categories of small, medium, and large.

Even though the latest explorations of wearable technology have certain limitations, they expand any consumer’s imagination about the possibilities of future products. Be it a stunt or gimmick, the flying dress, Levi’s jacket, and IBM’s cognitive dress were able to reach a wider audience through social media, which provoked ongoing conversations. Smart garments also expand beyond gadgets that measure body vitals, broadening a user’s interest. Several successful Kickstarter campaigns of heated jackets (able to generate heat powered by batteries) may suggest that textiles with beneficial and practical functions are not only wanted but needed. To bring the bespoke wearable technology to ready-to-wear, it will take time and effort to increase the demand and extend the technological capability. Here are a few examples with the potential for being the next foot-treadle sewing machine for wearables.

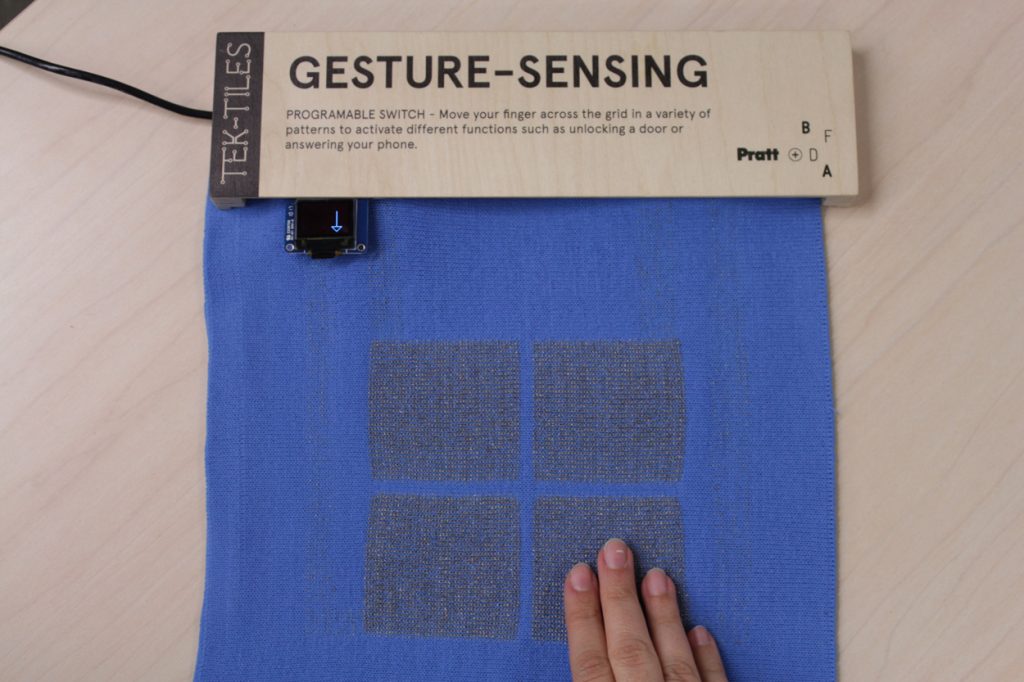

Sensing Textiles

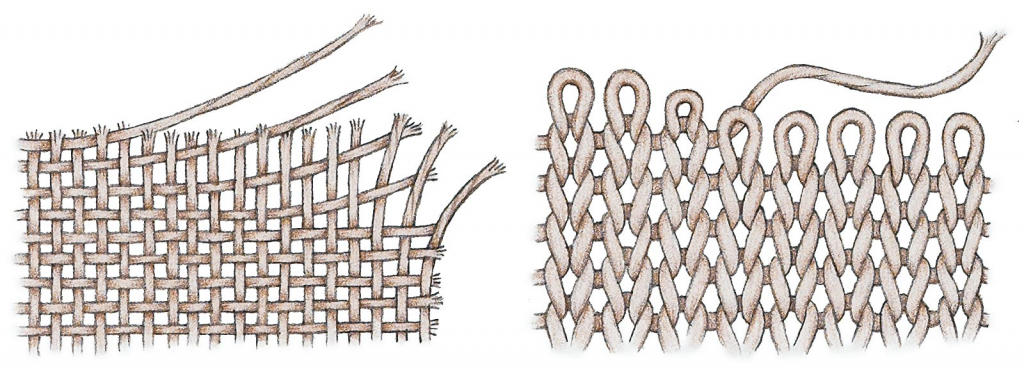

Computerized textile fabrication methods offer the opportunity to create textiles with a combination of yarns in intricate knitting patterns. Japanese high-tech knitting machine manufacturer Shima Seiki, for example, can knit a mixed stitch of conductive and non-conductive yarn together to create a sensing surface to detect different gestures. Textiles embedded with soft circuitry work just as well as devices with printed circuit boards for motion tracking and tactile feedback. As the surface area increases, the sensing function is not limited to one’s wrist.

Expressive Textiles

We choose what we wear not only because clothing keeps us warm, but because of personal preference; be it an expression of individuality or comfort. A personalized garment can bond our relationship to our clothing and slow down the pace of fast fashion. My Heart on My Dress is a bespoke garment that visualizes daily experiences and emotions through colors and patterns based on a real-time text analysis of a digital diary. This experimental project is created with the hope that with interactive personalization in garments, we can emphasize the individual connection to our clothing.

Production Solutions

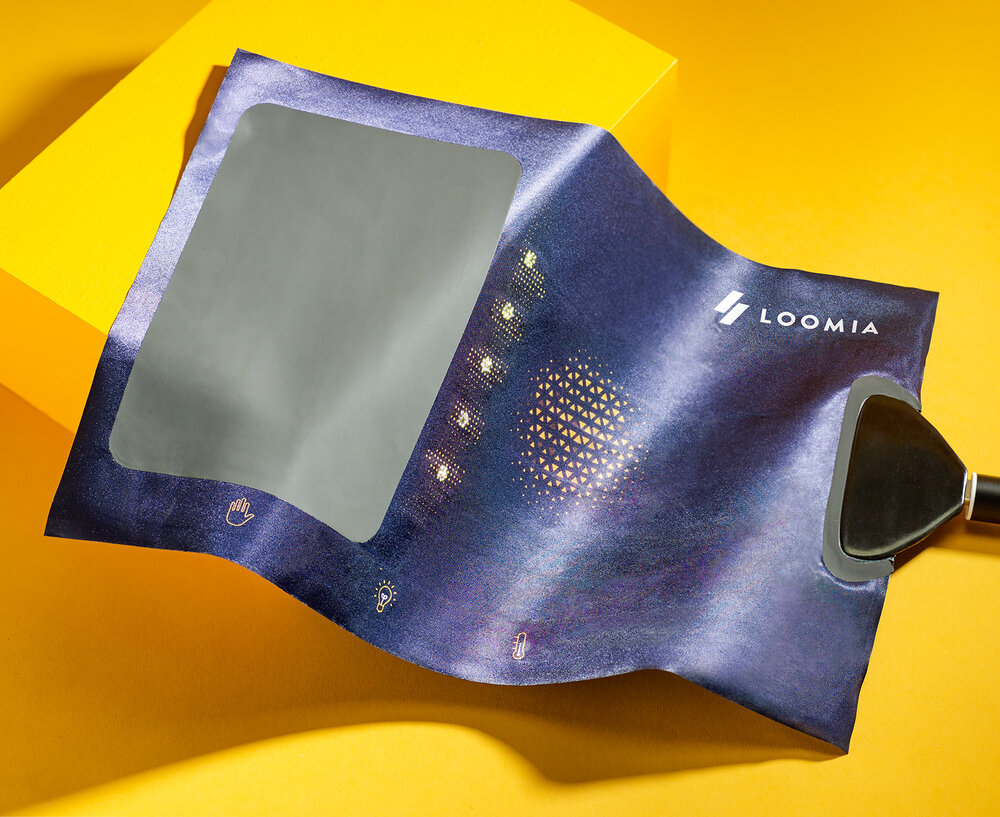

In order to create the bespoke technologies ready-to-wear, a production solution is necessary. Loomia, a company that makes textile layers with built-in electronic circuits, has been working on a scalable solution to mass produce the soft circuitry possible. The ultra thin electronic layer, which provides touch-sensing, lighting and heating, can be easily sewn onto clothes without disrupting the garment manufacturing process.

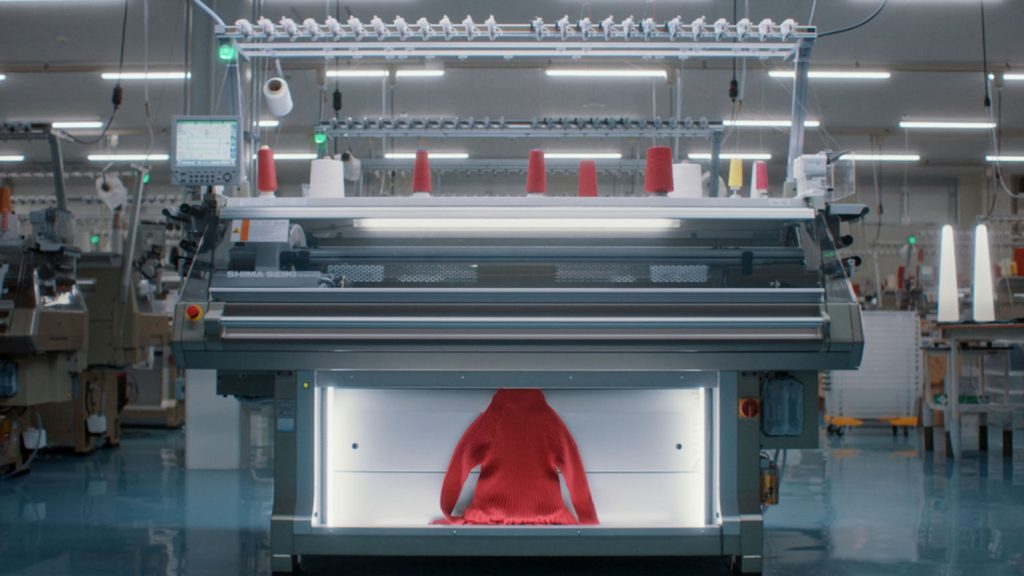

3D knitting provides opportunities to create textiles with personalized garment designs. Like 3D printing, 3D knitting machines can knit customized patterns three-dimensionally as one entire piece in one shot. For designers, this method offers more precise control than traditional weaving, allowing for experimentation with the fabric. The e-method can potentially blur the lines between labor-intensive tailored apparel and mass-produced clothing. An additional benefit of 3d knitting is its efficiency in the production process. Using the exact amount of yarn without creating waste, makes it more sustainable than traditional methods.

The usage of these techniques perform as the rudder of the ship, but in the long run, it is in the hands of each designer, what the next generation of smart clothing will look like. What we are asking of wearables is what we ask of all technologies, to enhance or augment the capabilities. If wearables become more ubiquitous in the future, more conversations about security and privacy in consumer electronics need to be part of the overall strategy. Whether we’re looking at bespoke or ready-to-wear, this innovation is being worn on human bodies, requiring a solid understanding of human needs and industry regulations to prevent us from developing invasive and unsuitable tech-enabled apparel. Between conductive fabrics and sensor-clad smart garments, wearables are more than strapping a screen on a user’s wrist or inserting a sensor in a bracelet.

Luckily, we are not in a fog over the future of wearables. There are promising, scalable technologies and production solutions to bridge the gap between bespoke and ready-to-wear. Sensing textiles can provide fitness tracking for daily workouts and gather vital information for healthcare and competitive sports. Not only can expressive textiles start new fashion trends, but they can also create alternative ways of communicating for assistive technology. Even if some of the technologies are not ready-to-wear yet, they bring meaningful insights to the industry, while continuously inspiring designers, technologists, brands and manufacturers.

Tomorrow is a new day. What will you be wearing?