Inspirations

The idea to make fishing lures out of the agar agar bioplastic came from our friend Tres. He’s really into fish right now and said he would actually try out our bioplastic lures on his next fishing trip. We did some research on what fishing lures look like and got to work.

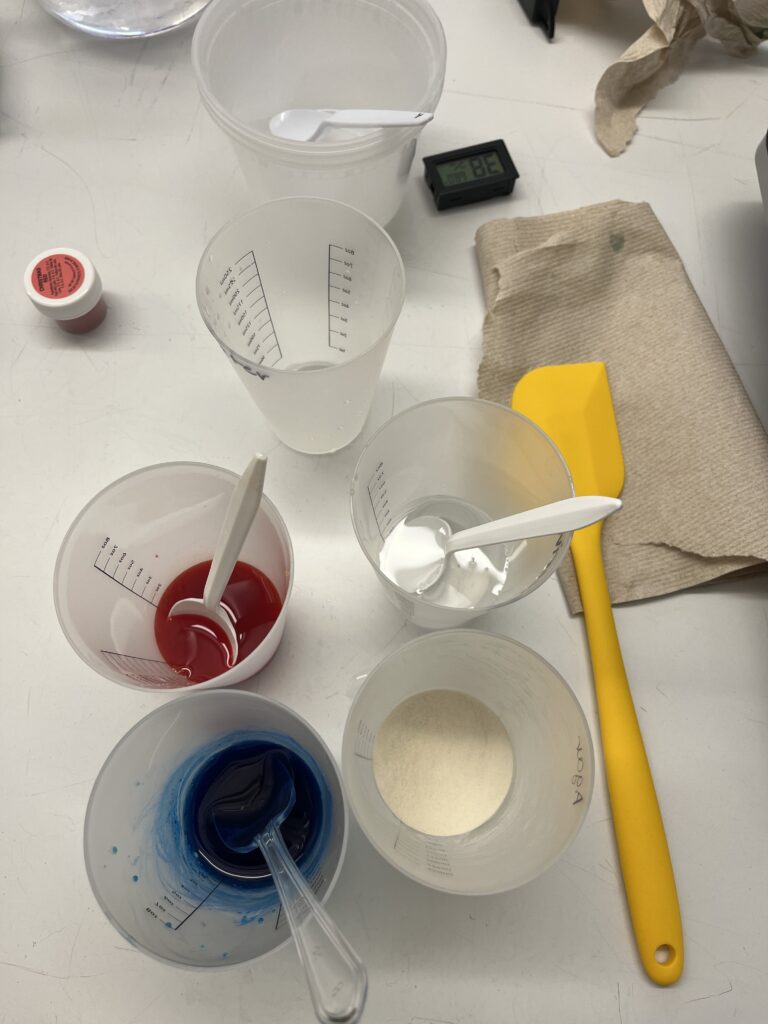

Materials

To make these fishing lures we needed the basic cooking equipment:

- Hot plate

- Non-stick pot

- Spatula

- Baking tray

- Kitchen scale

- Containers and spoons

- Paper towels

And then some equipment for cutting:

- Laser cutter (optional)

- X-acto knife and cutting mat

Recipe

Ingredients:

- Water = 800mL

- Agar agar = 30g

- Glycerin = 80g

- 1/2 capful of vinegar

- Yellow food coloring

- Color solutions: 40g of water + red/blue food coloring

Instructions:

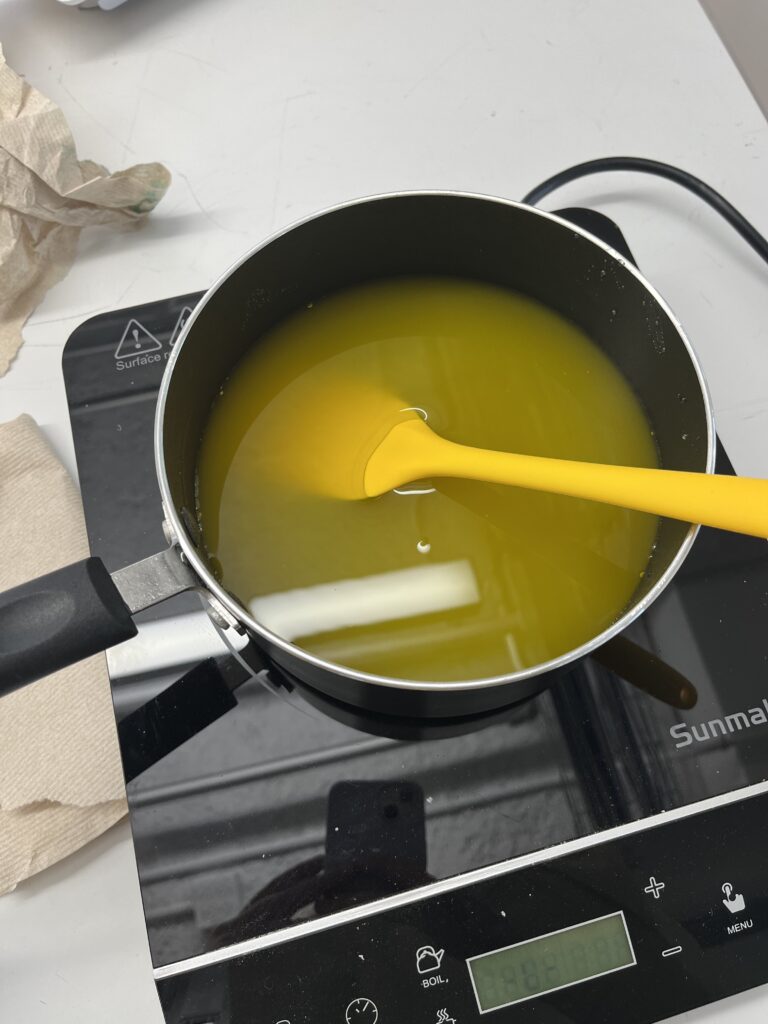

- Mix up water, agar agar, glycerin, and vinegar in the non-stick pot

- Add base color food coloring until desired color is reached. In our case, we chose yellow.

- Put pot on hotplate and cook for 5 minutes at 140 degrees F, using the spatula to stir slowly

- Continue stirring while cooking: at 176 degrees for 5 minutes, 212 for 5 minutes, 176 for 7 minutes

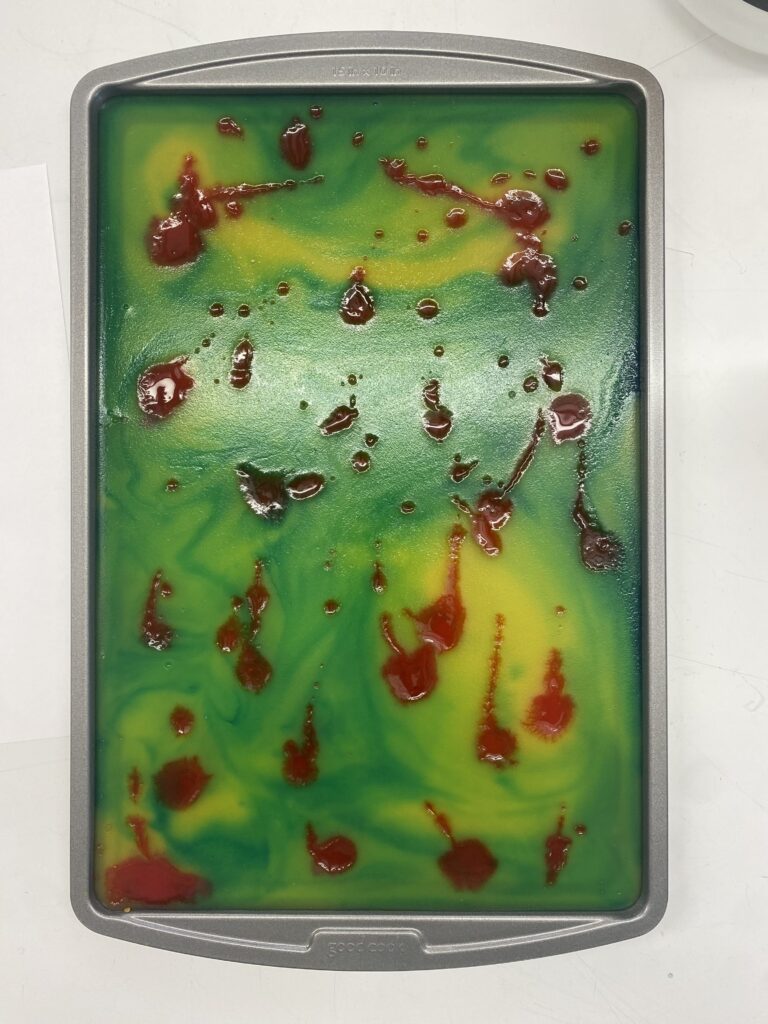

- You can exercise your artistic freedom when it comes to coloring: pour blue food coloring mixture into pot and do a couple of stirs to get a marbled effect

- Pour the multi-colored mixture into the baking sheet quickly and gently

- Drop in the red food coloring mixture (or whatever color you choose!) on top of the sheet for extra color

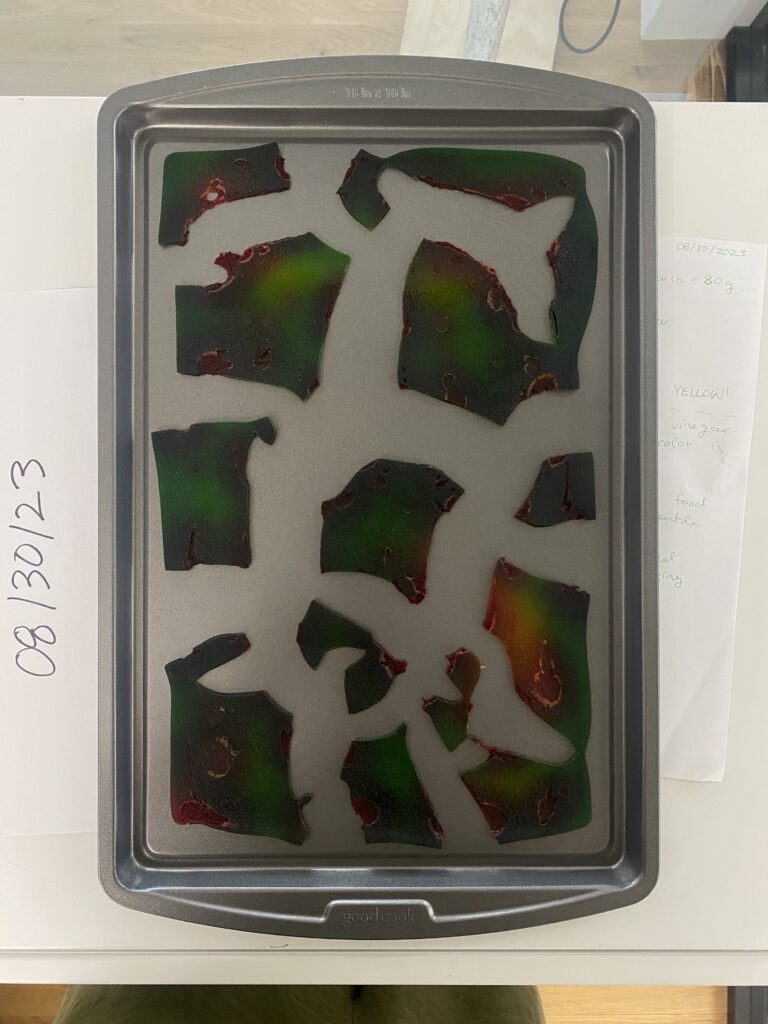

Process

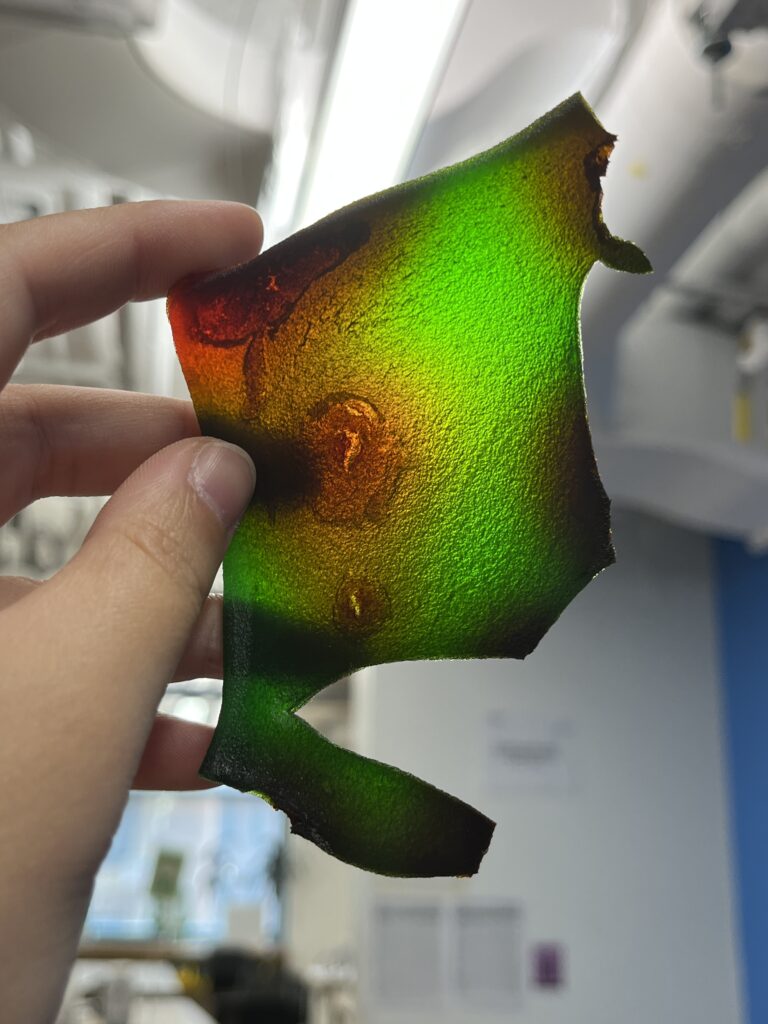

Once the colorful bioplastic was cooked we let it sit for around 5 days. It broke apart into different pieces during the drying process which was something completely unexpected. My guess is that the red food coloring mixture splattered on top of the sheet at the end made holes for the material to break apart. All that aside, rhe color of the dried plastic turned out really beautiful!

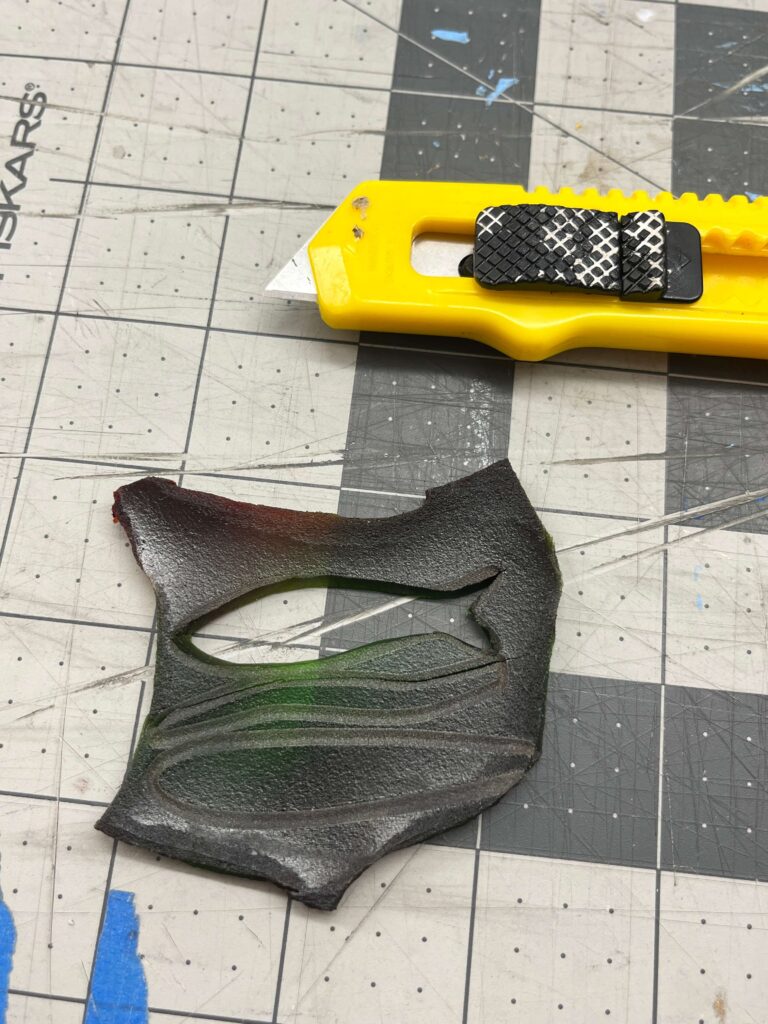

To cut out the fish, we thought we would try the laser cutter. We tried out various power and speed settings but it turns out the water content is too high for the laser to cut all the way through our material.

However, the marks left by the laser cutter serve as a great guide for cutting out the fish shapes by hand.

Final Product

Lessons Learned

We still have lots to learn when it comes to laser cutting a biomaterial. The recipe used for this batch was too flexible and had too much water content, even after drying. A bioplastic that is more rigid (and dry) will work better for laser cutting.

Tres has yet to try out these lures on an actual fishing trip. Check back for future updates…