Acrylic plastic is a commonly used material at ITP/IMA to create prototypes or different elements of projects. Chemically, it is known at polymethyl methacrylate (PMMA) and like many other plastics, it is made from petroleum. The process of making acrylic plastic is an energy intensive process because high temperatures and pressure is needed to create polymers. To produce 1 kg of acrylic, 2 kg of oil is required, and approximately 6 kg of CO2 is released into the atmosphere (read more).

Acrylic is not a very sustainable material choice because it can take up to 200 years for it to decompose and also releases greenhouse gasses and toxic chemicals into the environment (read more). It’s possible to recycle but most companies do not recycle acrylic because the process of depolymerization takes a lot of energy.

What are the alternatives?

If you’re looking for easy off-the-shelf options that are more sustainable than virgin acrylics, we’ve identified two kinds of recycled acrylics: chemically recycled and mechanically recycled acrylics. Below are some options that we’ve identified.

Chemically recycled acrylics

Acrylic plastic, PMMA, is a polymer which goes through a process called depolymerization when it is recycled. Depolymerization uses solvents and heat to turn polymers back into smaller molecules, which are then fed back into the plastic production process.

The options below are great because they look and feel like the virgin acrylic you’re familiar with and can be bought online.

Delvie’s Plastics Eco Green

This acrylic only comes in clear, 1/8 inch thickness. But it is a really great deal of $10 for a 12 x 24 inch sheet!

Recrylic

Comes in clear, white, and black. Custom colors are a possibility as well! Thicknesses vary. At the moment, it can only be bought in large quantities, but might still be a relevant resource for some.

Find more information here and don’t hesitate to reach out for samples or quotes!

Green Cast

This is a company based in Europe. They have very many recycled acrylic products with a wide range of colors. We never got a response or any material samples but products look too good to be true!

Mechanically recycled plastic

Mechanical recycling is the process of collecting, sorting, cleaning, shredding, and reforming plastic using heat. Mechanically recycling plastic waste can be a fun, accessible, and guilt-free way to use plastic material in your art practice and make something beautiful.

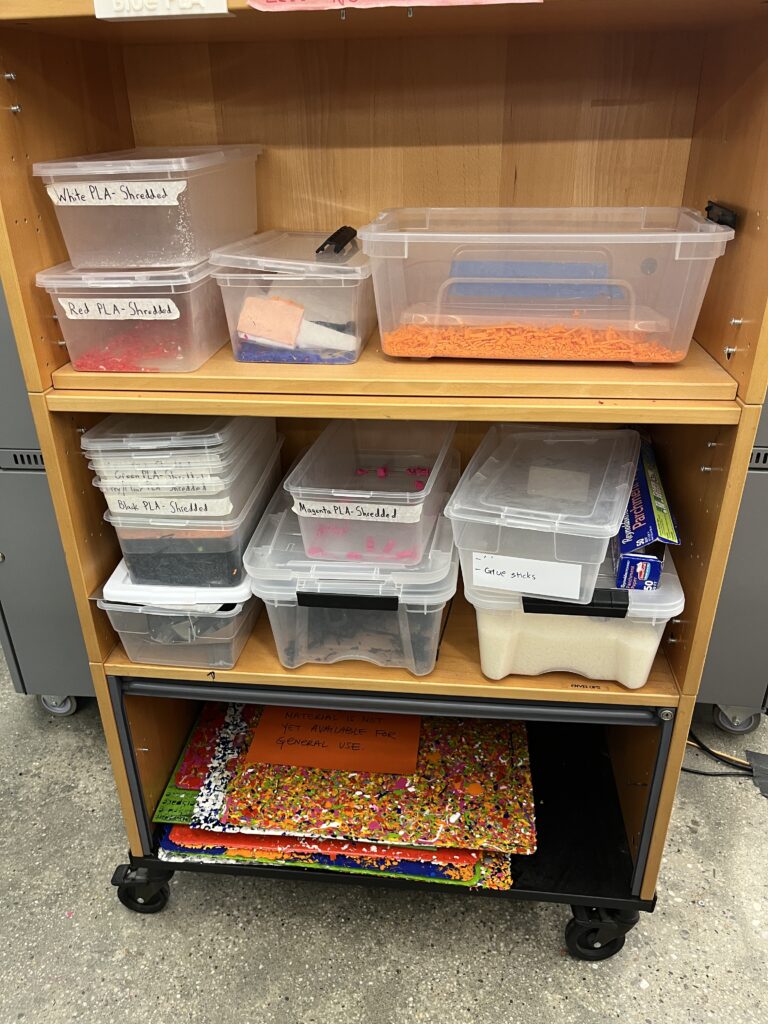

The Tandon MakerSpace across the street from ITP has a plastic shredder and pizza oven and they currently support making plastic sheets out of PLA scraps. They built the shredder following the curriculum from the non-profit Precious Plastics. They provide resources to start your own plastic recycling system and all the design files needed to build the machines.

Kay Wasil from Yeseul’s Sustainable Material Research Lab class created this ready-to-wear corset by ironing together plastic shopping bags. Learn more about the project here.

There are other great makers out there, like Brother’s Make, who take plastic recycling to a whole other level.

Mechanically recycled plastic sheets can even be used in the laser cutters in the ITP shop. Some drawbacks from recycling your own plastic is that it can require specialized equipment, extra time, and can lead to unpredictable results. There are also limitations on how many times you can mechanically recycle plastic scraps.

Further Reading / References

- Cradle to Cradle by William McDonough and Michael Braungart

- Green Plastics by E. S. Stevens

- Acrylic facts: Is Acrylic Bad for the Environment?

- Chemical Recycling

- Is Acrylic Plastic Recyclable? (And Is It Biodegradable?)

- Introduction to sustainability and the textile supply chain and its environmental impact