Inspirations

Throughout our summer research, we were really interested in using the biomaterials we were developing as a material for mechanism. Because of their flexible and sometimes elastic nature, we figured the bioplastic could work well in making a timing belt. A timing belt is a usually a rubber loop which, when paired with a motor, can make linear movements. They are found in many x-y axis machines like laser cutters and 3D printers.

Materials

- One sheet of regular agar agar bioplastic

- Water = 800 mL, agar agar = 30g, vegetable glycerin = 60g

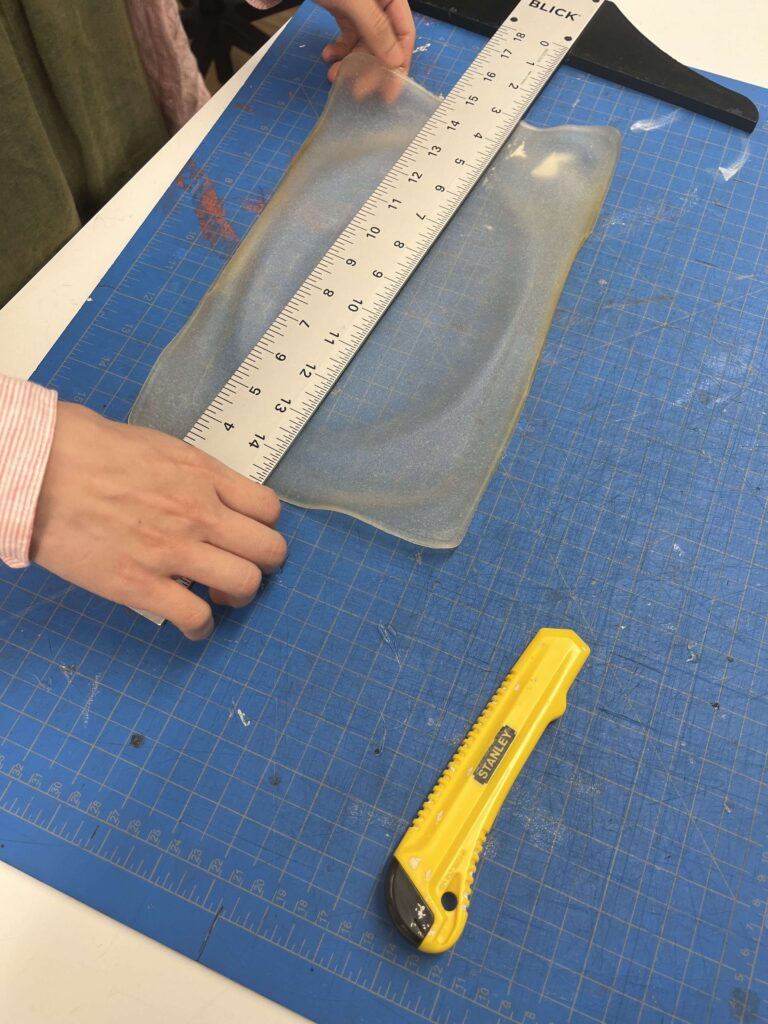

- X-acto knife, ruler, cutting mat

- Needle and thread

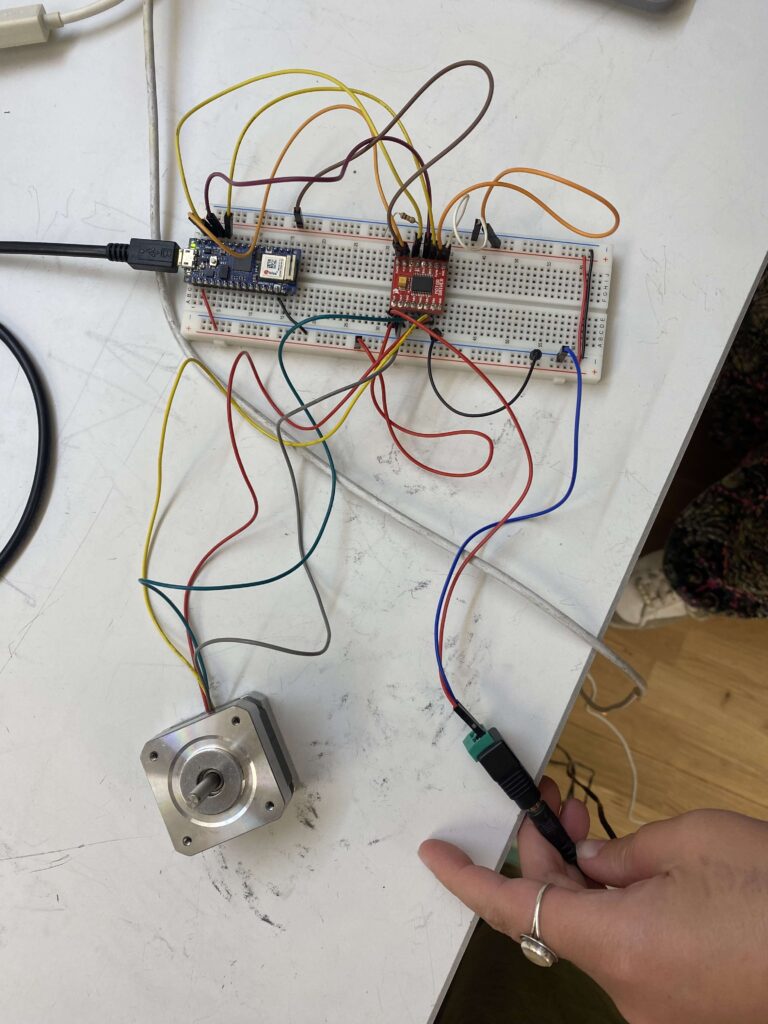

- Physical computing components

- Stepper motor

- Motor driver (TB6612FNG)

- Arduino Nano 33 IoT, micro USB cable

- Motor power supply

- Wires

- Breadboard

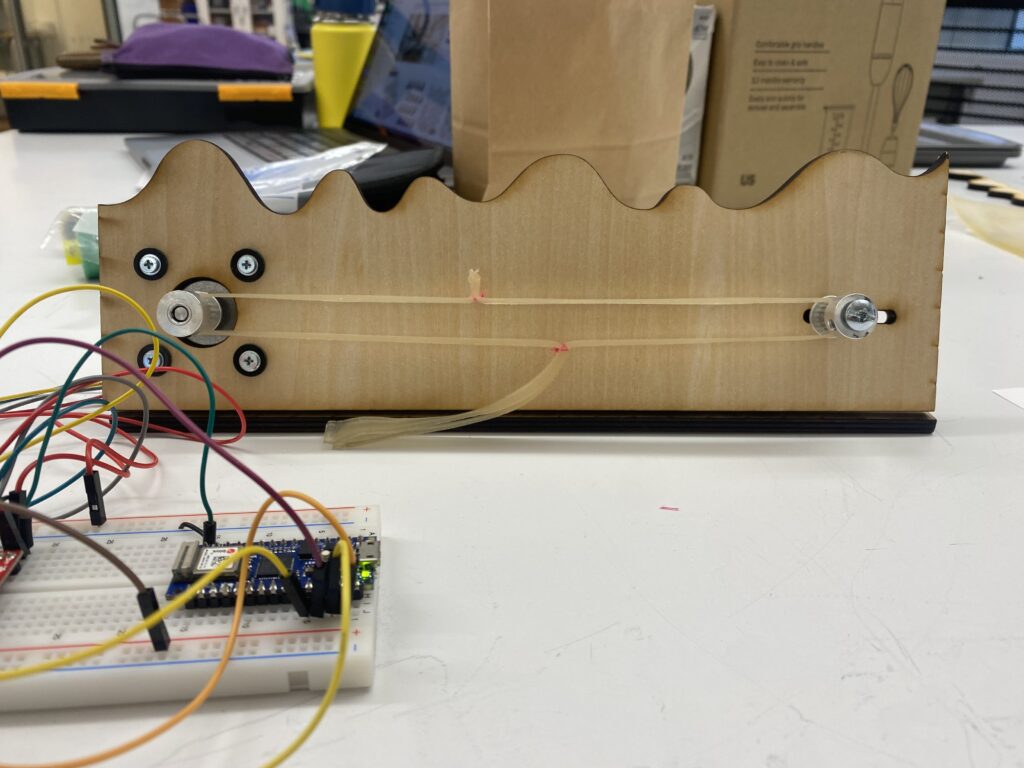

- Some material to make an enclosure to mount the motor. In our case we used scrap plywood.

- Screws and nuts to mount the motor

Process

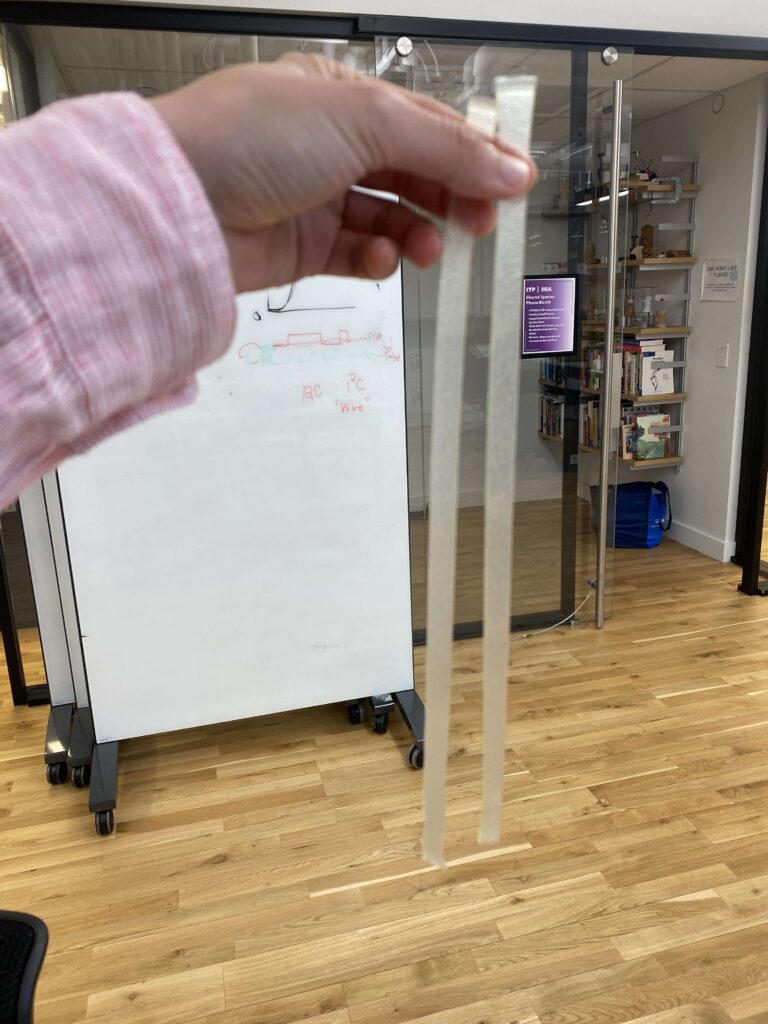

Cut bioplastic sheet into long, thin strips that will fit the hubs of your timing belt system. We found that measuring and cutting with a knife worked well but sometimes we needed to cut the belt a bit thinner with scissors to fit on the motor shaft hardware just right.

We sewed the bioplastic strips together to form the timing belt loop.

Once we had our timing belt made we put together a stepper motor circuit and made sure it worked. We followed this Physical Computing Lab.

After sourcing all the correct screws, hubs, and brackets, we designed an enclosure for all the electronic components and motor in Illustrator. We laser cut our design on some left over plywood. Then we used brackets to assemble the enclosure and mounted the motor and timing belt using our hardware.

Final Product

Lessons Learned

This project was also on display and constantly running for the duration of the *This is Not A Drill* exhibition. The timing belt broke repeatedly, always at the joint where it was sewed together. We had some back-up timing belts handy and experimented with using staples to construct the belt too. We learned that the holes made when sewing or stapling the belt weakens the strength of the belt. The bioplastic itself can get stretched out over time, so maybe a bioplastic made of gelatin would be more appropriate for making mechanisms because it makes a stronger plastic.